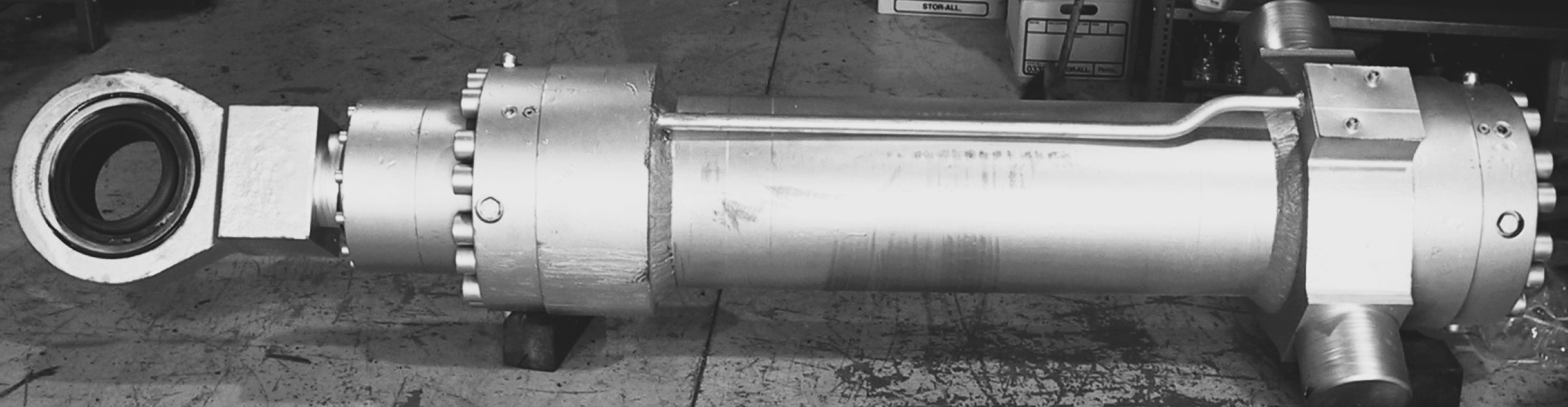

MacroMotion Fluid Power is an authorized distributor of Parker Hydraulic Rotary Actuators. We also specialize in servicing and repairing Rack-and-Pinion, Vane-type and Helical style rotary actuators. Click the button below to submit a request for quote or explore the Hydraulic Rotary Actuator Accessories available in our online store.