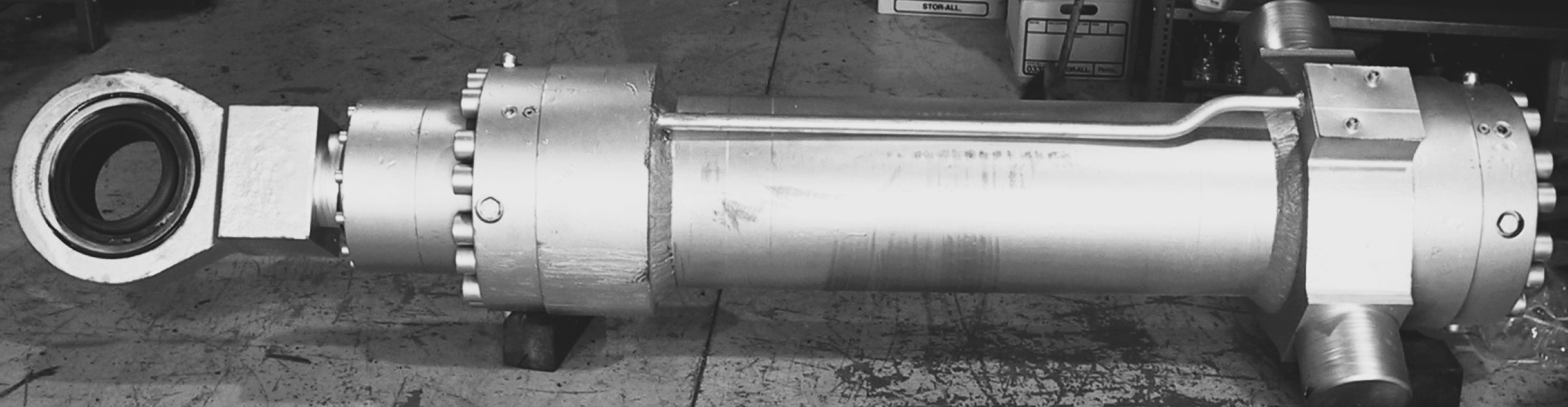

Hydraulics

MacroMotion is an authorized distributor of Parker Hydraulic products. Click here to learn more about our Hydraulic product offerings.

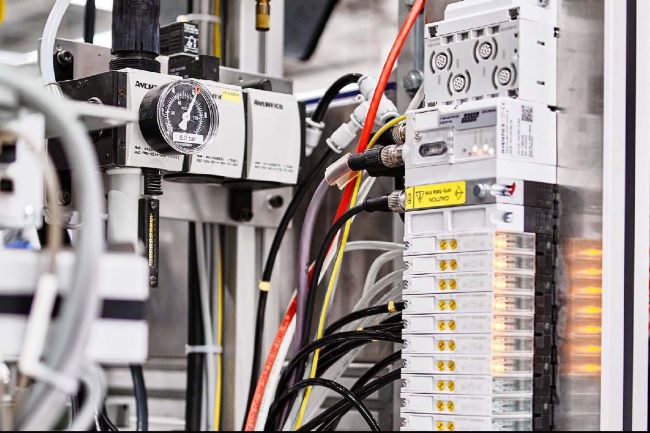

Pneumatics

MacroMotion is an authorized distributor of Aventics Pneumatic products. Click here to learn more about our Pneumatic product offerings.

Industrial Process

MacroMotion is an authorized distributor of ASCO Process products. Click here to learn more about our Industrial Process product offerings.

Instrumentation

MacroMotion is an authorized distributor of Winters Instruments. Click here to learn more about our Instrumentation product offerings.

Hose & Connectors

MacroMotion is an authorized distributor of Continental ContiTech. Click here to learn more about our Hose & Connector product offerings.